transfer point components

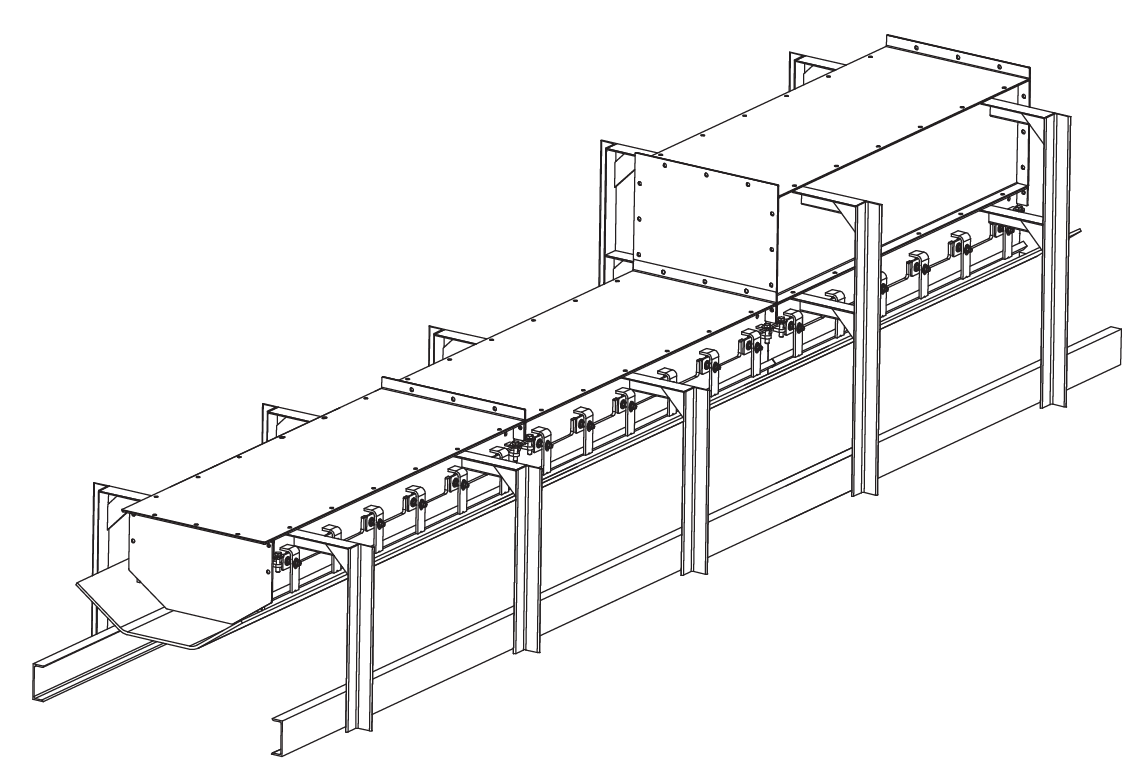

At a conveyor-to-conveyor transfer point, the material is usually in some state of free fall, creating and releasing forces that can turn into dust and spillage problems. The addition of properly designed settling and stilling zones connected to the load zone functions as passive dust control, minimizing air velocity through the extended enclosure.

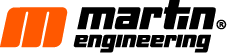

load zone

When material is transferred from one belt to another, it may strike the receiving conveyor with high speed, energy, and force.

The material experiences excessive turbulence in this area. The load zone needs to be designed to control the initial impact of the material while maintaining its structural integrity.

-

Internal wear liners protect the chute wall

-

External wear liners protect skirting

-

Robust chute walls keep the material loaded into the center of the conveyor belt

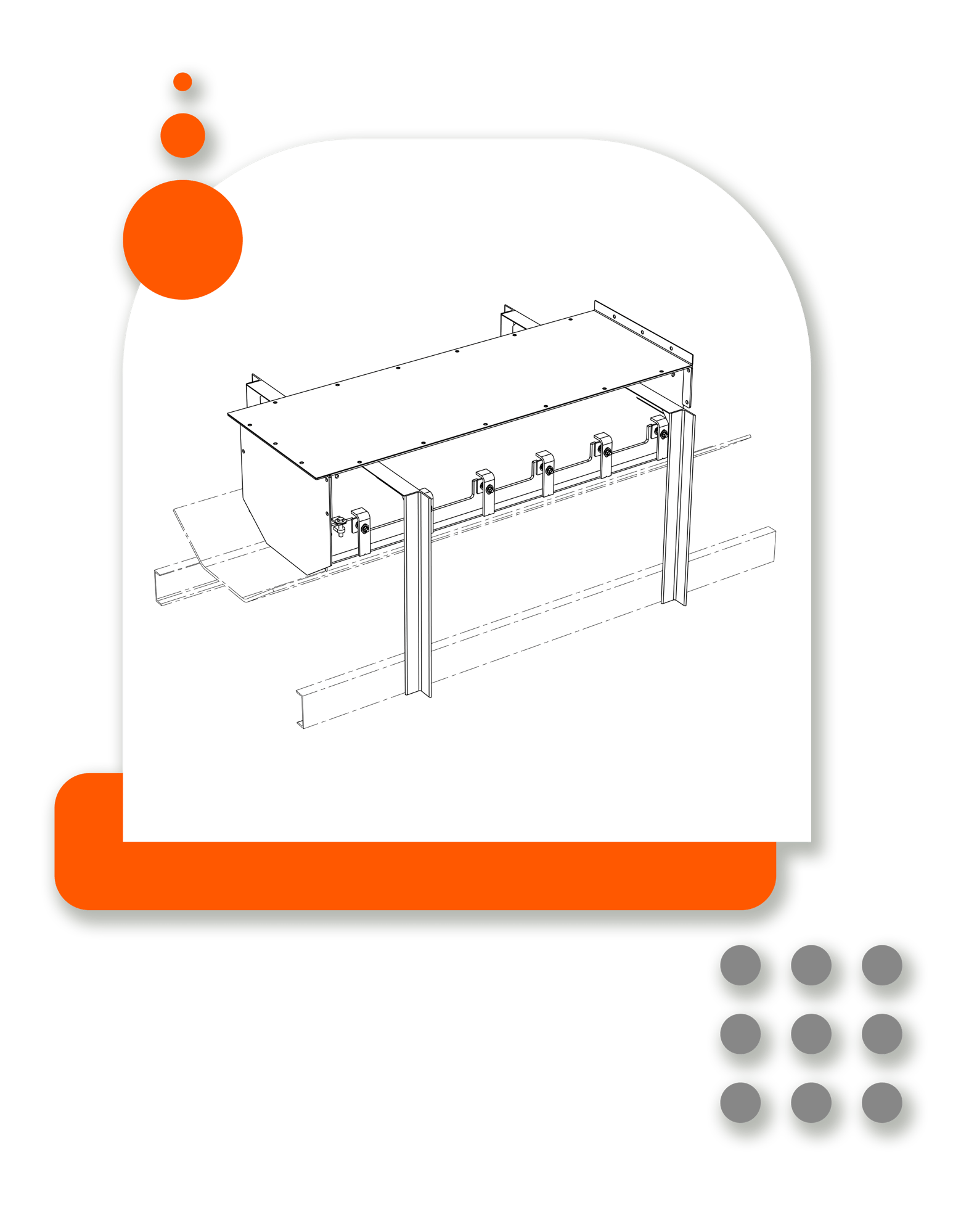

settling zone

Material must be allowed to settle into a controlled stream onto the conveyor belt. After product is placed onto a belt, this additional enclosed area allows the air to slow and material and dust to settle. The size of the settling zone is determined by site specifications such as; belt width and speed, chute width, airflow, depth of the material bed, and diameter of the largest lump of material. Dust curtains are strategically placed in this zone with a solid dust curtain at the entry point to reduce the air velocity and a slit curtain at the exit point to reduce dust.

-

External wear liners protect skirting

-

Dust curtains begin to control airflow

-

Chute walls contain the bulk of the material

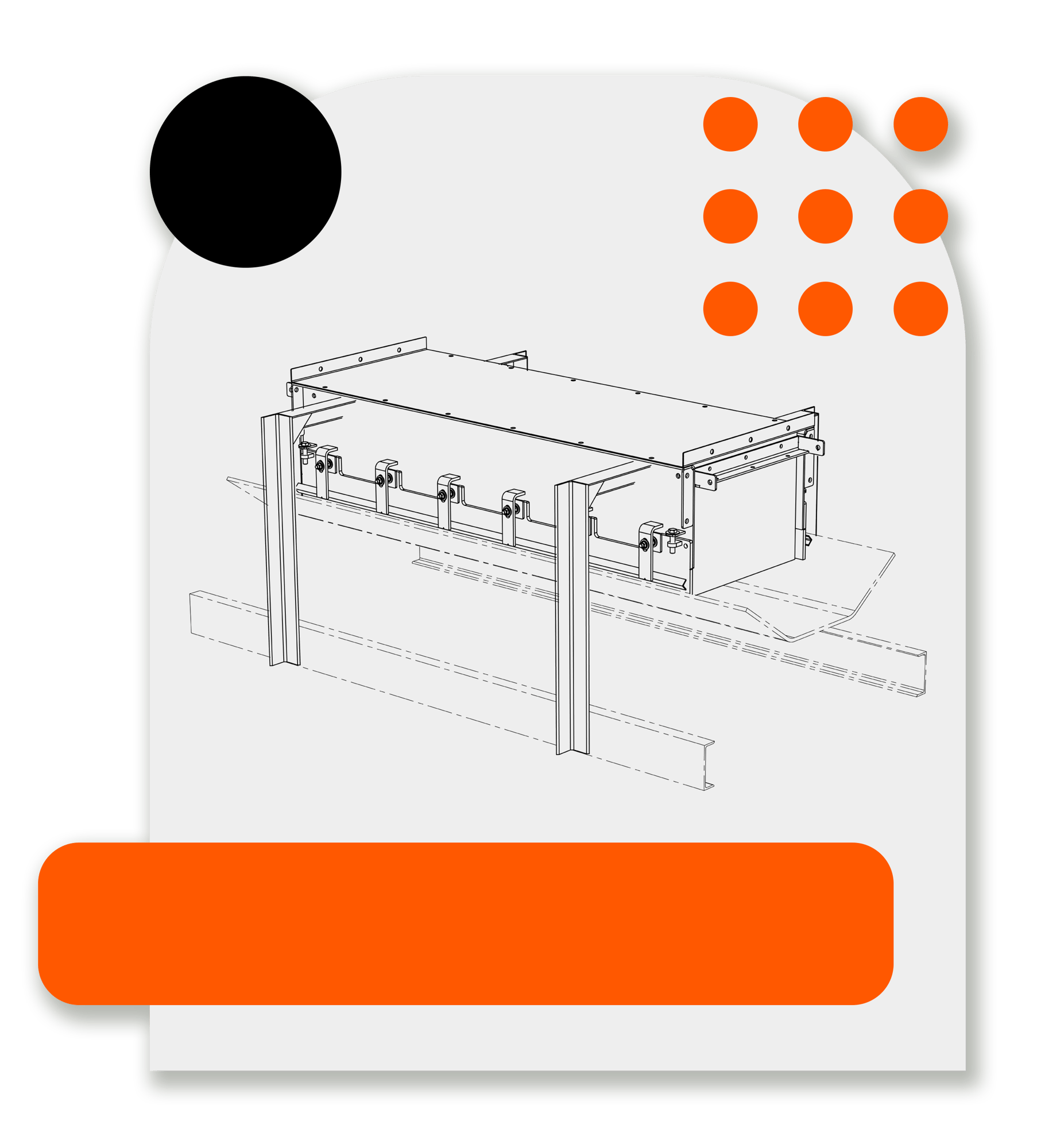

stilling zone

The process of transferring material from one belt to another creates airflow. This flow carries dust which can create workplace hazards, regulatory noncompliance, and equipment damage. In order to adequately slow airflow, additional volume is needed. This is achieved by extending the chute wall height. This region takes an aggressive geometric approach to dust curtain design that includes a staggered pattern to reduce air velocity and allow agglomerated dust to settle and rejoin the material before it leaves the transfer point.

-

Chute walls are extended to help reduce airflow

-

External wear liner protects skirting

-

Multiple dust curtains reduce airflow

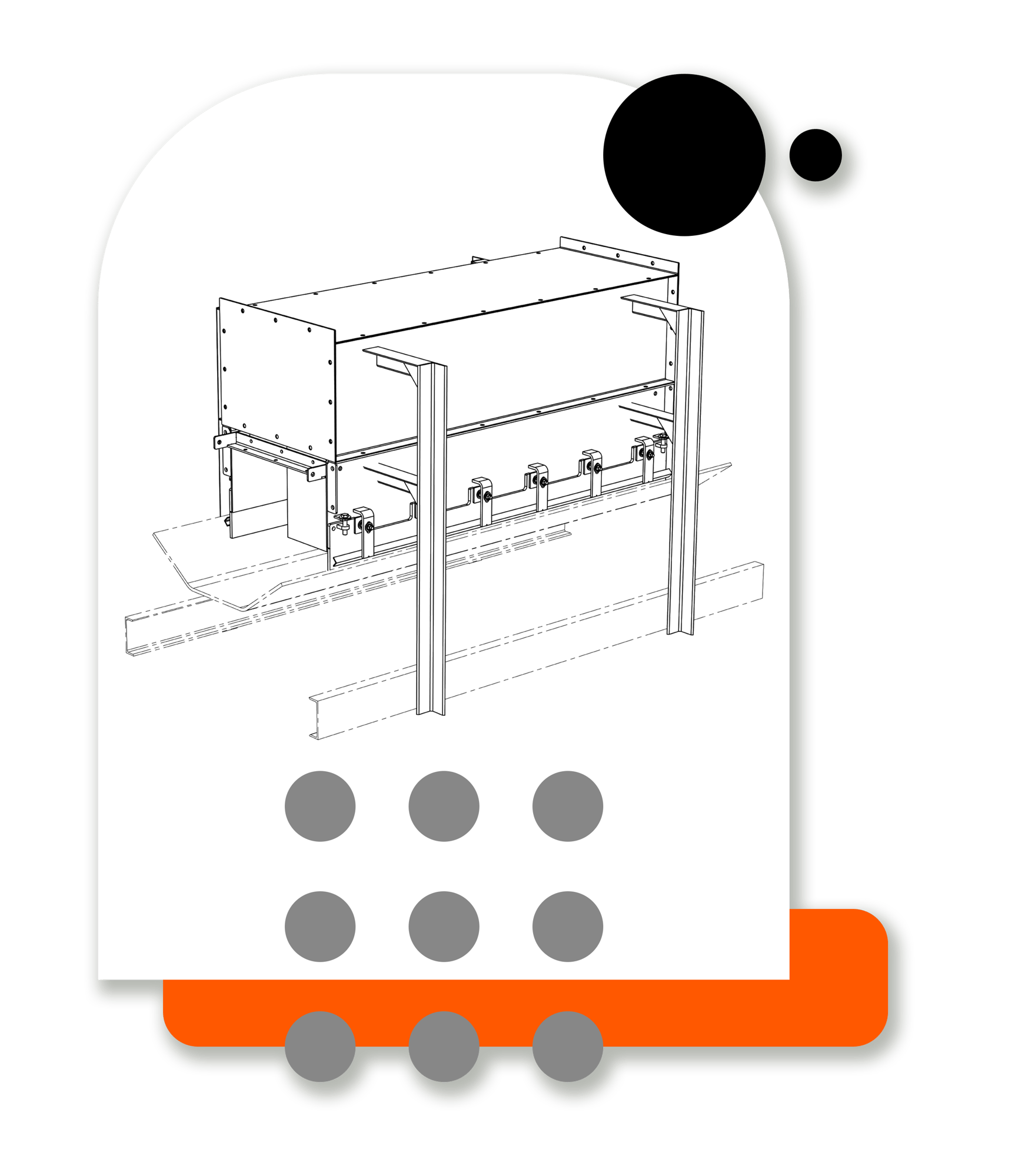

simplify your process

Transfer point kits include modular loading, settling, and stilling zone configurations and a wide variety of chute options to facilitate future upgrades. The kit simplifies the installation process, reducing the labor required for assembly and allowing the system to be pre-built prior to installation for reduced system downtime. The result is faster installation with less labor and shorter shutdowns, increasing the return on investment (ROI).

Each kit is either ordered as a loading zone, settling zone, or stilling zone. The width of the kit is determined by the receiving belt’s width and speed and the dust characteristics of the material being transferred. 4-ft or 6-ft lengths available. ApronSeal™ must be ordered separately to accommodate the total length of the transfer point.

What's included in my kit?

Load Zone |

Settling Zone |

Stilling Zone |

|

|

Chute Wall Weldment |

|||

|

External Wearliner Assembly |

|||

|

Outer Chute Supports |

|||

|

Top Cover |

|||

|

ApronSeal™ Clamps |

|||

|

Owner's Manual |

|||

|

Installation Hardware |

|||

|

Dust Curtains |

|||

|

Inner Chute Wall Supports |

|||

|

Internal Wear Liner |

|||

|

Tail Panel, Clamp, & Rubber Sheet |

*ApronSeal™ must be ordered separately to accommodate the total length of the transfer point.